How companies design and build products today drastically differs from a decade ago. As a result, designers and engineers have access to a wide range of materials and components, enabling them to build products with enhanced functionality and user experience. One such component that has significantly impacted product design is tactile dome switches.

What are Tactile Dome Switches?

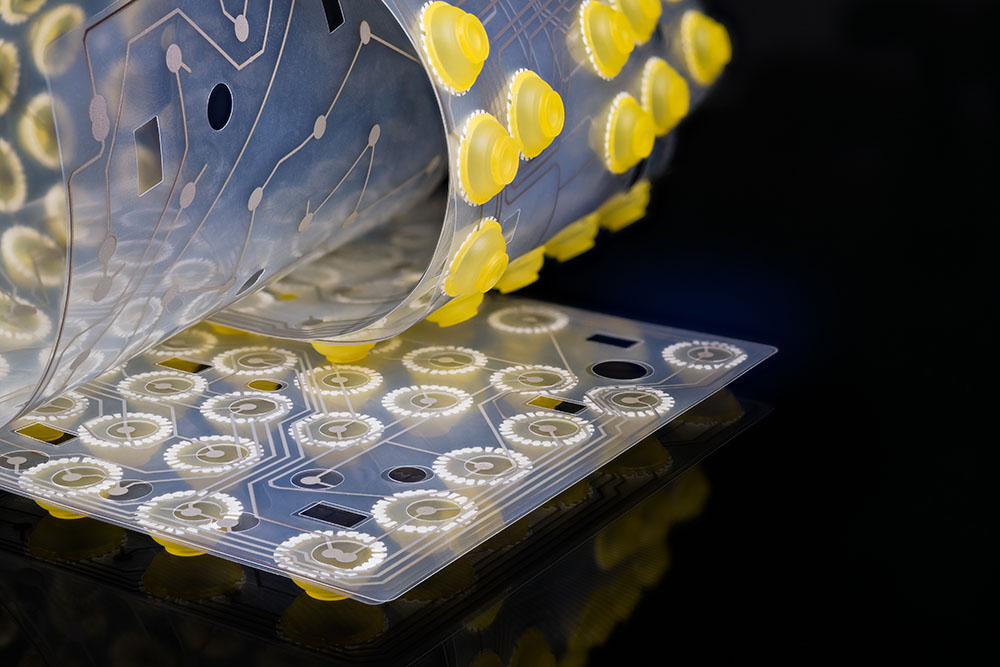

Tactile dome switches, also known as snap domes or metal domes, are momentary contacts that trigger a specific action when pressed. They are commonly used in electronics, such as keypads, gaming consoles, and medical devices.

Dome switches are made from a conductive material, such as stainless steel, that is placed on top of a circuit board. When pressed, the dome makes contact with conductive plating on the circuit board, which triggers an electrical connection.

The most common use for dome switches is with momentary contact, typically used in products requiring a single action to be triggered. For example, a momentary contact switch is used in a key fob to unlock a car door.

Benefits of Dome Switches

Tactile dome switches offer many benefits for product design. They are relatively inexpensive and easy to install, which makes them ideal for mass production. They also provide tactile feedback, which helps the user understand when a specific action has been triggered.

Metal dome switches are also highly durable and reliable. In addition, they are designed to withstand a wide range of environmental conditions, such as extreme temperatures, moisture, and dust. This makes them ideal for use in rugged environments and harsh conditions.

Another benefit of tactile dome switches is that they are highly customizable. They come in various shapes, sizes, and forces. In addition, they are one of the most low-profile switches on the market and have high life cycle ratings–up to 10 million cycles. These benefits make it easy to design a product that fits a particular aesthetic or feel.

Common Applications

Tactile dome switches are commonly used in many products, including appliances, smart home devices, gaming controllers, and more. You will also find dome switches in various industrial applications, such as robots, test and automation equipment, industrial machinery, and many more.

In addition to the above, dome switches are also used in automotive applications. They are commonly found in the dashboard, as well as doors, steering wheels, and other areas of the vehicle.

How to Select the Right Switch

When selecting a tactile dome switch for a particular product, there are a few factors to consider. First, the type of switch you choose will depend on the purpose of the product and the environment in which you use it.

The size of the switch is also essential. You will want to ensure that the switch you choose is the right size for the product you are designing. If the switch is too large, it will take up too much space on the circuitry and could affect the overall design. On the other hand, if the switch is too small, it may not be able to handle the amount of use required.

The type of overlay, actuator, or membrane that goes over the switch is also essential. Overlays, actuators, and membranes are the mechanical components of a switch assembly that contact the dome to press it down. They also act as a protective casing to protect the switch from dirt and dust. These materials often enhance the feel of a switch and minimize damage to the dome. The material should be durable, as it must withstand various environmental conditions.

Finally, consider the type of contact used. Tactile switches are a common choice, but some products may require a toggle, rotary, push button – or a combination of switches.

Disadvantages of Metal Dome Switches

Although dome switches offer many benefits, there are a few drawbacks to consider. One of the main drawbacks is that they are limited in terms of functionality. For example, most momentary contact switches can only trigger a single action, which may not be ideal for some applications. However, some unique dome switch offerings, like the RCG-Series, can help minimize these effects.

In addition, tactile dome switches can be difficult to repair or replace. Due to their small size, it can be challenging to access the switch’s internal components. This can make it difficult to diagnose issues or make repairs.

Finally, metal dome switches can be sensitive to dirt and dust. If these contaminants build up on the surface of the switch, it can affect its performance.

Conclusion

Tactile dome switches are a popular and cost-effective component that you can use to enhance the user experience of a product. They are highly customizable and offer several benefits in terms of durability, reliability, and tactile feedback.

When designing a product that utilizes tactile dome switches, it is vital to consider the switch’s size, material, type of contact, and protective casing. You must also test the switch before the product is put into production. By following these best practices, designers and engineers can create a product that offers an enhanced user experience.

If you want to order or inquire about incorporating dome switches into your product design, contact Snaptron today.