When designing any product that involves user input—from industrial control panels to consumer electronics—selecting the right keyboard switch is a decision that can significantly impact performance, user satisfaction, and product longevity. The term keyboard switch refers to the component beneath each key that registers a press and sends an electrical signal to the device. And while there are many types of switches available—mechanical, membrane, scissor, and capacitive—dome switches offer a compelling blend of tactile feedback, durability, and design flexibility.

In this article, we’ll explore the different types of keyboard switches, zoom in on the anatomy and benefits of dome switches, and offer technical tips for designing with domes in mind. Whether you’re developing ruggedized equipment, medical devices, or high-performance instrumentation, dome switches could be your best-kept secret for responsive, reliable input.

Understanding the Different Types of Keyboard Switches

Before we dive into dome switches specifically, it’s important to understand the main categories of keyboard switches:

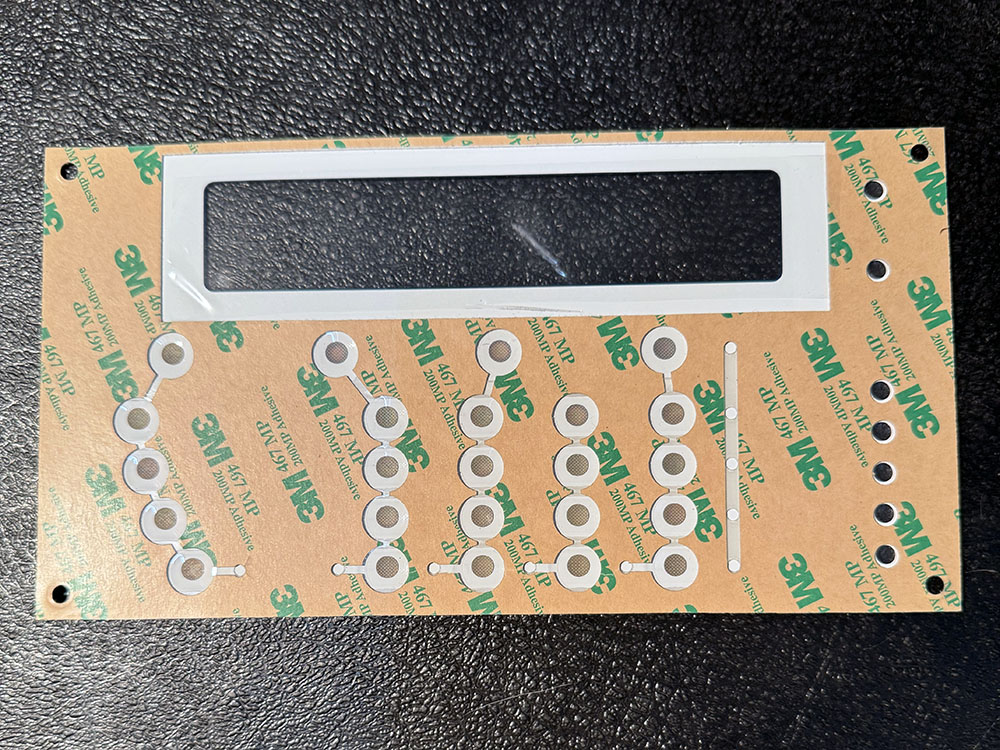

1. Membrane Switches

Membrane switches use a flexible overlay with conductive traces that close a circuit when pressed. They’re compact, inexpensive, and often used in appliances, remote controls, and medical devices. The trade-off is typically a “mushy” feel with limited tactile feedback.

2. Scissor Switches

These are a hybrid of mechanical and membrane technologies often found in laptops. They use a stabilizing scissor mechanism for a short travel distance and quiet operation. While they offer a low profile, their design complexity and limited lifespan make them unsuitable for high-use or mission-critical environments.

3. Capacitive Switches

Instead of closing a circuit, capacitive switches sense a change in voltage or charge when a key is pressed. These are commonly used in touch keyboards and modern consumer devices. They offer little or no tactile feedback, and their performance can be affected by moisture or contaminants.

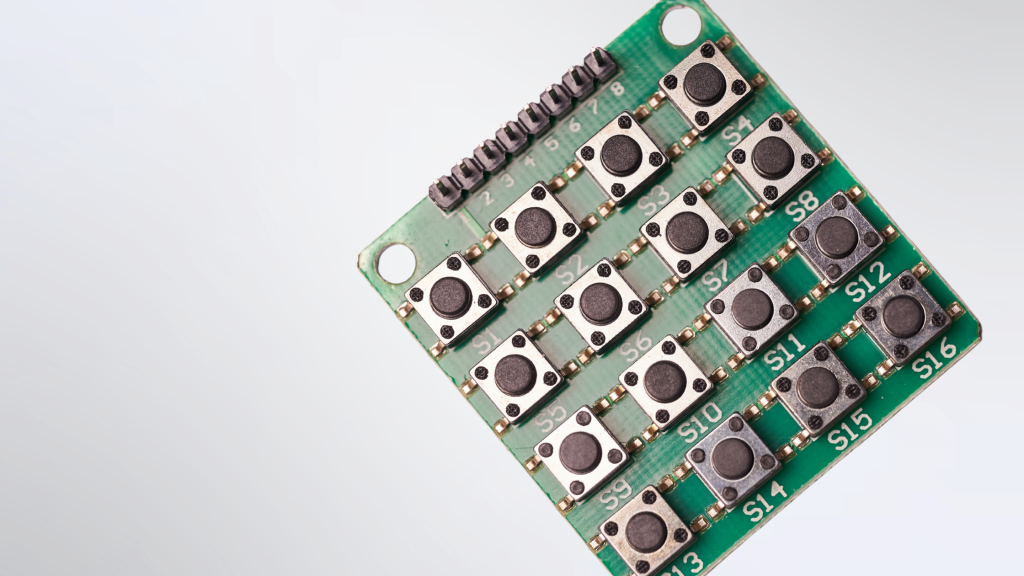

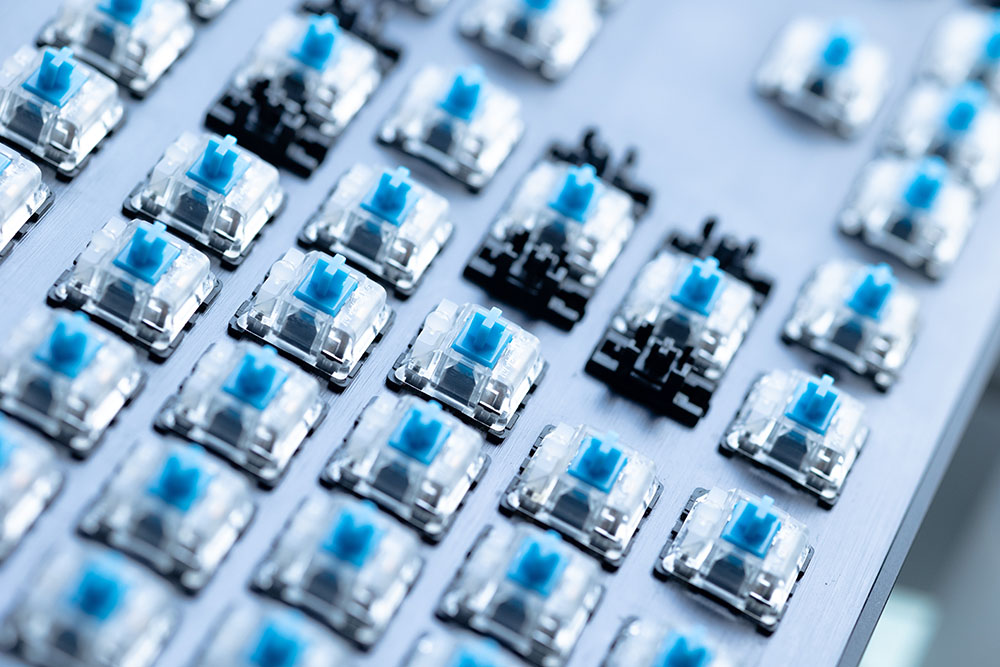

4. Mechanical Switches

Mechanical switches are made up of individual moving parts, including a stem, spring, and electrical contacts. Known for their distinct tactile or clicky feedback and long lifespan, mechanical switches are popular in gaming keyboards and industrial applications. However, they’re often bulkier and more expensive than other types.

What Are Dome Switches?

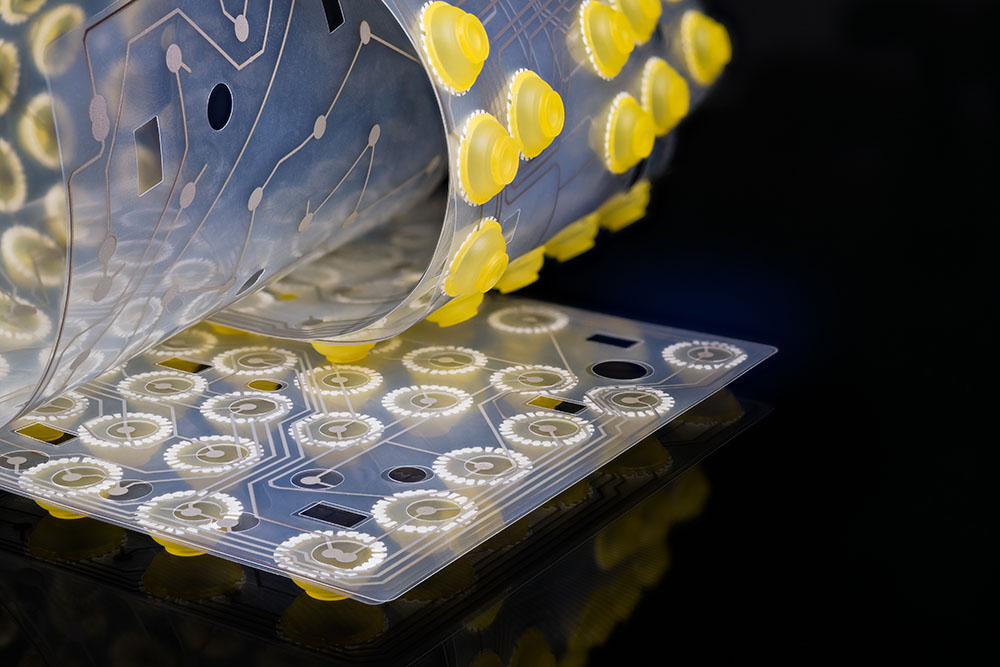

Dome switches, also known as metal dome switches or tactile domes, are a type of tactile switch used beneath keypads. When pressed, the dome collapses, completing a circuit and giving a crisp tactile “snap” or response to the user.

Dome switches are often used in:

- Industrial equipment

- Medical devices

- Consumer electronics

- Automotive dashboards

- Wearable and handheld devices

There are two major types of dome switches:

- Metal Dome Switches – Typically made from stainless steel or nickel-plated steel, offering high tactile feedback, long life cycles, and excellent conductivity.

- Polyester Dome Switches – Formed from printed polyester films. These are quieter and more flexible but may offer lower durability and tactile consistency.

Benefits of Dome Switches in Keypad Design

So why might you choose to design with dome switches over other types of keyboard switches? Let’s break it down:

1. Tactile Feedback

One of the most significant advantages of dome switches is their crisp, responsive tactile feel. The snap action gives users a physical confirmation that their input has been registered, which is essential in safety-critical or high-precision applications.

2. Low Profile Design

Metal dome switches are incredibly thin—often less than 0.3 mm in height—making them ideal for applications where space is limited, like handheld medical devices or compact control panels.

3. High Life Cycle

Metal domes can withstand millions of actuations. For example, Snaptron’s domes are tested to exceed five million actuations or 10 million in some cases, depending on dome type and actuation force. This makes them suitable for high-use environments where reliability is a must.

4. Customizability

Dome switches are highly customizable. Designers can specify actuation force, diameter, plating (gold, nickel), and more to achieve the exact performance characteristics needed for their product.

5. Cost-Effective

Compared to mechanical switches, dome switches offer a high-performance, tactile solution at a fraction of the cost—especially when integrated into custom membrane or PCB-based keypads.

How Dome Switches Work

At a basic level, a metal dome sits above a conductive trace on a PCB or membrane layer. When pressed, the dome collapses and makes contact with the trace below, completing the circuit. Once pressure is released, the dome returns to its original shape, ready for the next input.

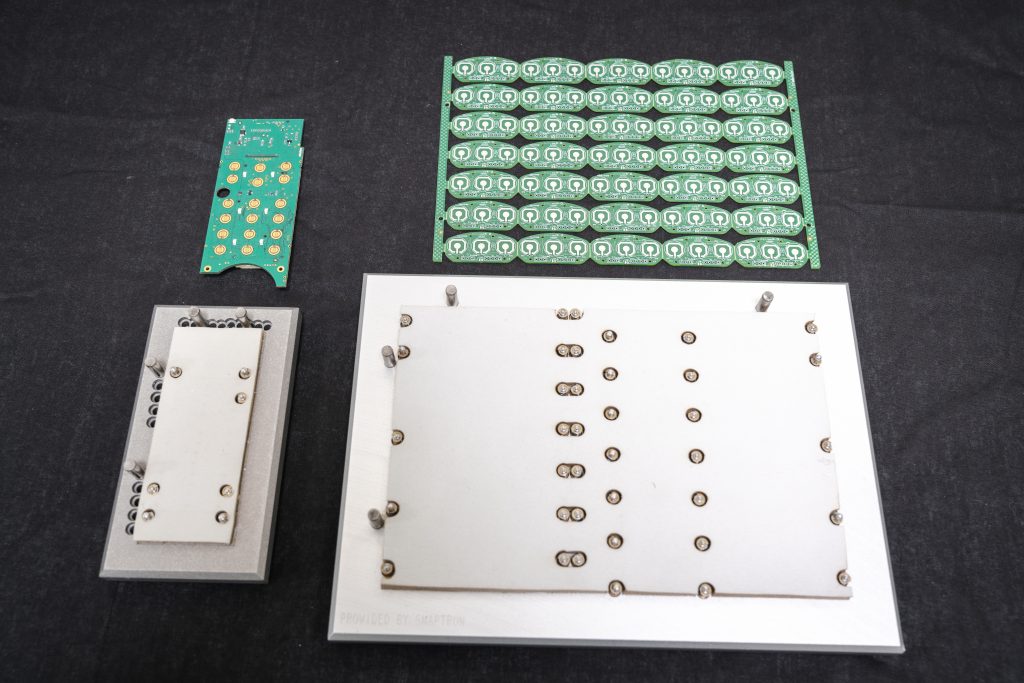

Most dome switches are integrated into dome arrays or switch matrices using adhesive-backed films for quick alignment and installation. These arrays can include multiple dome sizes, shapes, or actuation forces, giving designers granular control over the user experience.

Technical Design Tips for Using Dome Switches

If you’re considering dome switches in your next keypad design, here are some best practices:

1. Choose the Right Dome Size and Force

Dome sizes typically range from 4 mm to 35+ mm. Smaller domes require less actuation force but may offer less tactile feedback. Larger domes have a longer travel distance and more pronounced snap. Choose the size and force that match your application’s ergonomics.

Example:

- 6 mm dome – 180–250 gf (grams-force)

- 10 mm dome – 300–500 gf

2. Consider the Electrical Contact

Ensure the dome material and plating match your electrical requirements. Gold-plated domes offer better conductivity and corrosion resistance, ideal for medical or military environments.

3. Use an Application Fixture for Accuracy and Consistency

For production, use a placement fixture to ensure domes or arrays are aligned precisely with the PCB. This increases manufacturing speed, reduces errors, and ensures consistent actuation.

4. Venting and Environmental Sealing

Some designs require vented domes to reduce backpressure and improve tactile feel, especially in sealed enclosures. Be sure to account for air escape paths or add vent holes if needed.

5. PCB Design Considerations

When integrating dome switches directly on a PCB:

- Use gold or ENIG plating on the pads for the best contact

- Design the pad shape and spacing according to the dome spec

- Include locating features (like alignment holes or raised bosses) for array placement

6. Test Your Stack-Up Early

The feel of a dome switch can be affected by the overlay material, actuator, and housing geometry. Build early prototypes with your exact mechanical stack-up to fine-tune the user experience before full production.

When Not to Use Dome Switches

While dome switches are highly versatile, they may not be ideal for:

- Silent operation environments (unless using polyester domes)

- Applications requiring analog input or pressure sensitivity

- Designs where exposure to liquid ingress is severe, and sealing is difficult

Are Dome Switches Right for Your Design?

If your project requires a tactile, reliable, space-efficient switching solution, dome switches are hard to beat. They offer the best of both worlds: precision feel and durability at an accessible price point. Whether you’re building medical equipment, industrial controls, or consumer tech, dome switches provide the responsiveness and resilience that modern users expect.

Want to learn more or test dome switches in your design? Snaptron offers a range of off-the-shelf domes and custom dome array solutions for prototyping and production. Contact our engineering team for samples or expert guidance tailored to your application.