When designing user interfaces for electronics, the choice of switch technology is crucial. Understanding the differences between dome switches and membrane switches is key to achieving the desired balance of performance, durability, cost, and tactile feedback. These two types of switches may appear similar in some applications, but their internal mechanics, performance characteristics, and use cases vary significantly.

In this article, we’ll break down the key differences between dome switches and membrane switches, including their construction, actuation mechanics, tactile response, durability, and ideal use cases.

What Is a Dome Switch?

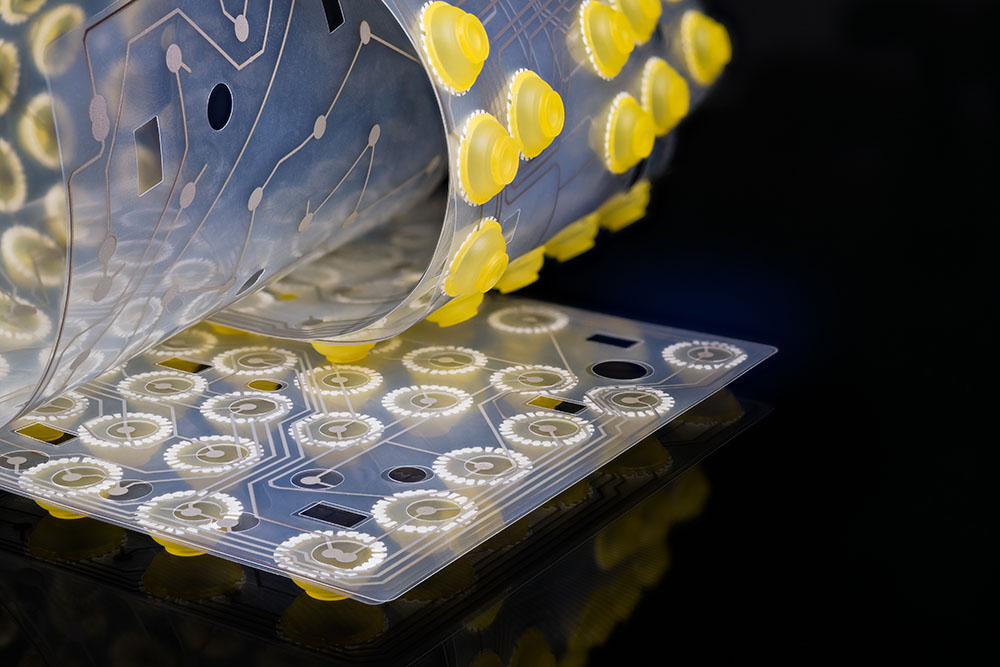

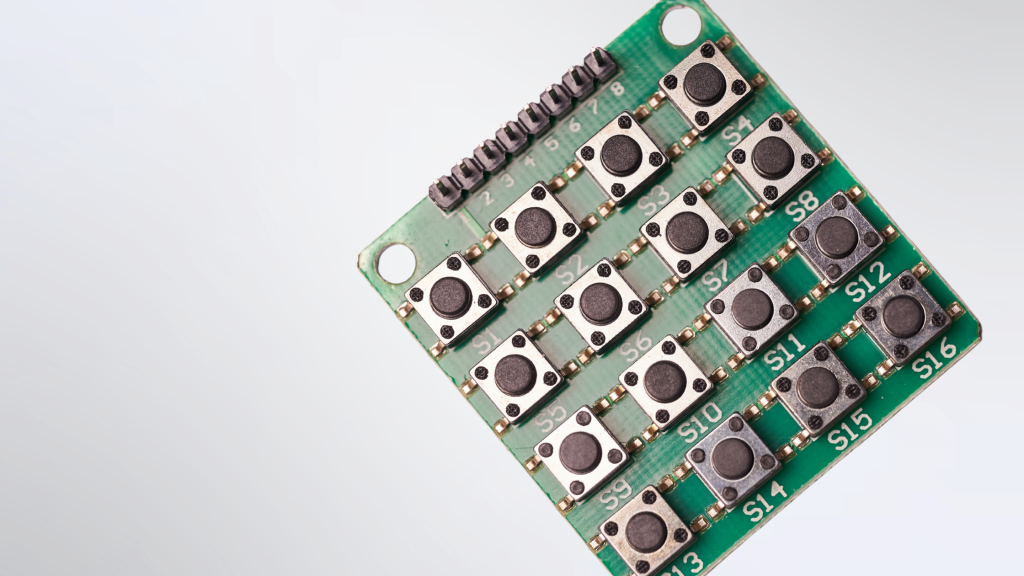

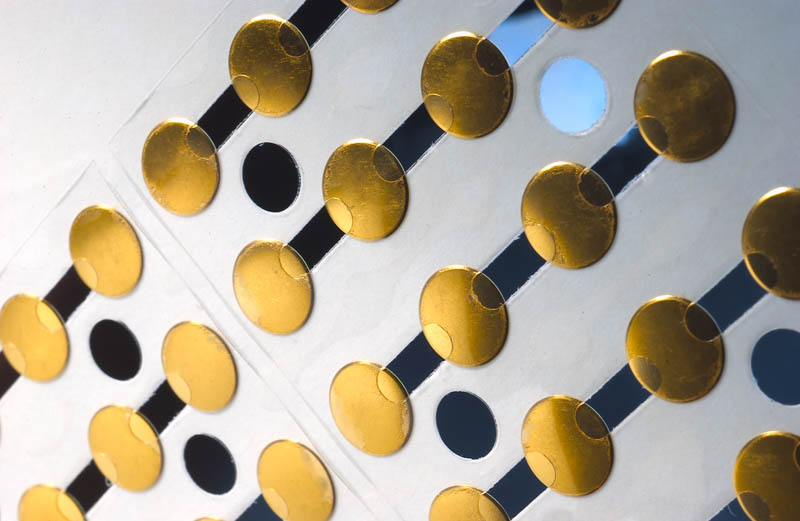

A dome switch is a type of momentary contact switch that uses a small metal or polyester dome as the actuation mechanism. When pressed, the dome collapses and makes contact with a conductive trace on a printed circuit board (PCB) or flexible circuit, completing the electrical circuit.

Key Components:

- Metal or polyester dome: Typically made from stainless steel or polyester/polycarbonate films.

- PCB or flex circuit: The circuit where the dome sits.

- Spacer and overlay: Used in some applications to position the dome or add a graphic user interface (GUI).

Characteristics:

- Tactile feedback: Sharp, crisp response when actuated.

- Actuation force: Customizable (e.g., 180g–700g), depending on dome geometry.

- Travel distance: Typically 0.1 mm to 0.6 mm.

- High cycle life: Metal domes can last up to five million actuations or more.

What Is a Membrane Switch?

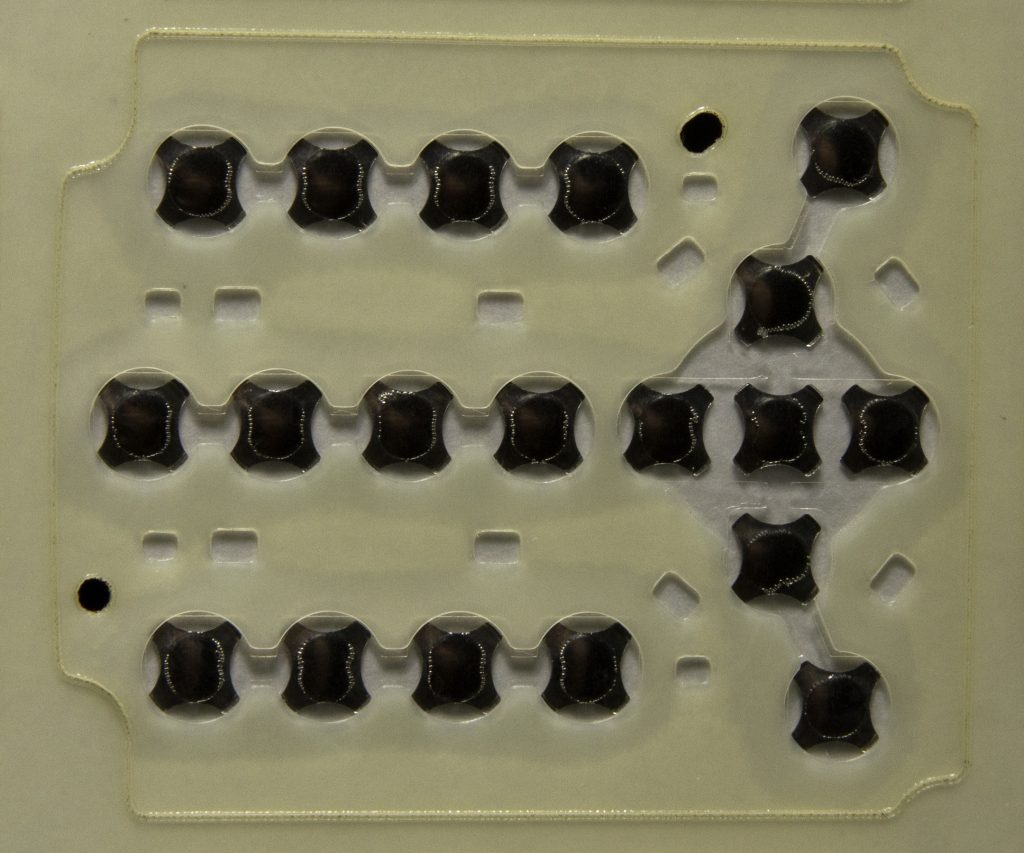

A membrane switch is a type of low-profile switch composed of several layers of flexible materials, typically polyester or polycarbonate. These layers include printed conductive traces and actuation zones that collapse when pressed, enabling an electrical connection.

Key Layers:

- Top graphic overlay: Printed user interface.

- Spacer layer: Separates the circuit layers.

- Upper and lower circuit layers: Printed conductive inks.

- Domes (optional): Some membrane switches incorporate tactile domes for feedback.

Characteristics:

- Non-tactile or tactile response: Without domes, feedback is soft or absent.

- Actuation force: Generally lighter than metal domes.

- Travel distance: Minimal—often <0.2 mm.

- Lower cycle life: Typically 1 million cycles or less.

Dome Switch vs. Membrane Switch: Side-by-Side Comparison

| Feature | Dome Switch | Membrane |

| Tactile Feedback | Strong, crisp tactile response | Soft to none (unless dome-enhanced) |

| Actuation Force | Customizable (medium to high) | Light to medium |

| Durability | Up to 10 million cycles | ~1 million cycles |

| Construction | Metal/plastic dome over PCB or flex circuit | Multi-layer printed circuit structure |

| Cost | Lower per-unit cost | Lower per unit cost |

| Travel Distance | 0.1 mm to 0.6 mm | Minimal (<0.2 mm) |

| Size/Footprint | Compact, low profile | Extremely thin |

| Customization | Highly customizable (force, shape, materials) | Customizable graphics, limited mechanical tuning |

| Noise | Audible snap (metal dome) | Quiet operation |

| Common Applications | Medical devices, military, automotive, test tools | Microwaves, remote controls, appliances |

When to Use Dome Switches

Dome switches are ideal for applications that require precise, consistent tactile feedback and high durability. Engineers and designers often prefer dome switches in environments where:

- User confirmation is critical: The tactile snap helps users verify the input like in defense applications.

- High actuation life is required: Metal domes outperform tact switches in longevity.

- Environmental sealing is possible: Dome switches can be sealed with many different options.

- Performance matters more than cost: Dome switches are slightly more expensive but offer better performance.

Industries that often use dome switches:

- Medical devices (diagnostic tools, wearable monitors, surgical tools)

- Industrial controls

- Military, aerospace, and aviation

- Automotive (dashboards and steering wheel interfaces)

- Consumer electronics (keyboards, handheld devices, wearables)

When to Use Membrane Switches

Membrane switches are best suited for applications where low profile, cost-efficiency, and light use are more critical than tactile feedback or high cycle life.

Ideal scenarios include:

- Cost-sensitive products: High-volume consumer electronics and appliances.

- Space-constrained designs: Ultra-thin construction suits small devices.

- Basic input functionality: Minimal feedback or user interaction.

Common applications:

- Appliances (microwave ovens)

- Remote controls

- Computers and office equipment

- Entry-level medical devices

Technical Advantages of Dome Switches

From an engineering perspective, dome switches offer distinct advantages:

- Defined Force Curve: Engineers can tune the force vs. travel profile to match human ergonomics.

- High Reliability: Metal domes withstand high-cycle environments with consistent resistance and conductivity.

- Diagnostic Compatibility: Paired with test systems like Snaptron’s Sapphire Switch Tester, dome switches can be evaluated for actuation force, travel, tactile ratio, and return force in real-time.

- Ease of Prototyping: Dome arrays can be sampled and tested quickly without complete assembly tooling.

These features make dome switches a go-to choice for high-precision and mission-critical applications.

Which Switch Should You Choose?

Choosing between a dome switch and a membrane switch is not just about their technical differences, but also about understanding your application’s specific needs. If your application demands tactile feedback, long life, and robust performance, dome switches are likely the better choice. If budget and space savings are more important and your product does not require a strong tactile response, membrane switches can be sufficient. This understanding should reassure you about your decision-making process.

As a rule of thumb:

- Go with dome switches if your users need clear feedback, your product will be used intensively, or precision input is essential.

- Choose membrane switches if your product is disposable, used infrequently, or primarily cost-driven.

Both dome and membrane switches have their place in modern electronics. Understanding their mechanical design, performance trade-offs, and application-specific strengths will help you make the right decision during product development.

Snaptron specializes in high-performance tactile dome switches that can be customized to meet your exact application requirements. Whether you’re designing a wearable medical device, an automotive interface, or a custom control panel, our engineering team can help you select the right dome for optimal performance.

Need help selecting a switch? Contact Snaptron today to request samples or consult with an engineer.