Designing a high-performance user interface is all about the right feel. Whether it’s a medical device that demands reliability or a rugged industrial controller that must withstand the elements, integrating tactile metal domes into your PCB design requires both precision and foresight. Done correctly, and the result is a durable, responsive interface. Done poorly, it can lead to costly revision and diminished performance.

This article dives into best practices for integrating tactile metal domes into PCB-based interfaces, offering practical tips and guidance engineers can use. Let’s snap to it.

1. Understanding Dome + PCB Interactions

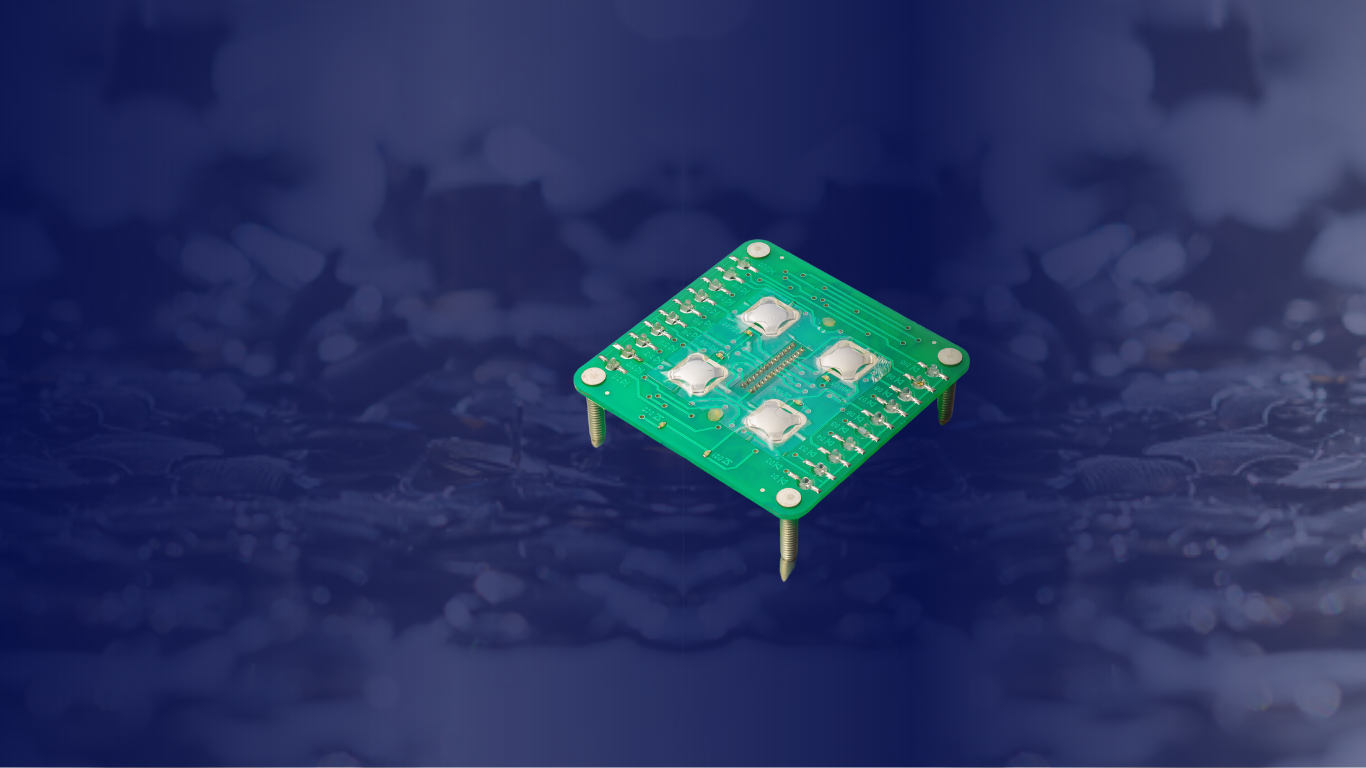

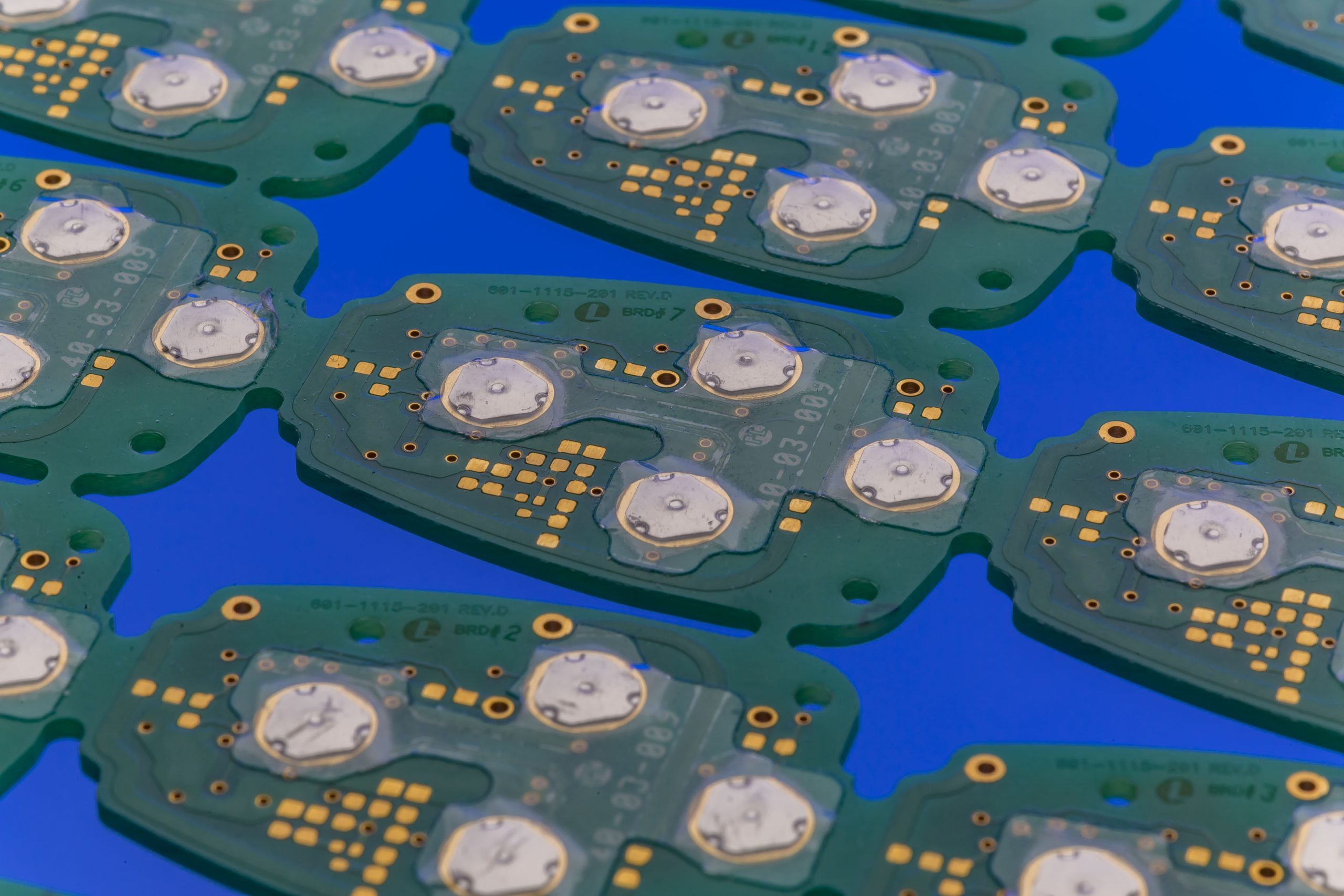

Before we dive into design tips, it helps to understand what’s happening under the hood. Tactile metal domes— engineered stainless-steel components—function as momentary contact switches. When pressed, they collapse, making contact with the underlying PCB trace or pad and completing a circuit. When released, they return to shape. They offer mechanical simplicity combined with electrical reliability.

Key considerations:

- Actuation Force Matters: Snaptron domes, for example, are available in forces ranging from featherlight to finger-wrestling strong. Choose based on your product’s audience and use case.

- Contact Resistance: A clean, solid connection is critical. Dome + pad design plays a big role here.

- Life Cycle Expectations: Many Snaptron domes are rated to five million actuations or more. PCB design must support that level of durability.

A note on plating and higher cycles: The typical choice of plating is ENIG; however, this type usually fails before 200,000 cycles. For life requirements up to one million cycles, we recommend hard gold or hard nickel PCB plating. For life requirements of one million cycles and above, we recommend hard gold or hard nickel plating with greater thicknesses. Exact recommendations can be found on page 27 of our design guide.

2. PCB Design Tips That Impact Performance

This is where theory meets trace. Your PCB layout is ground zero for tactile success.

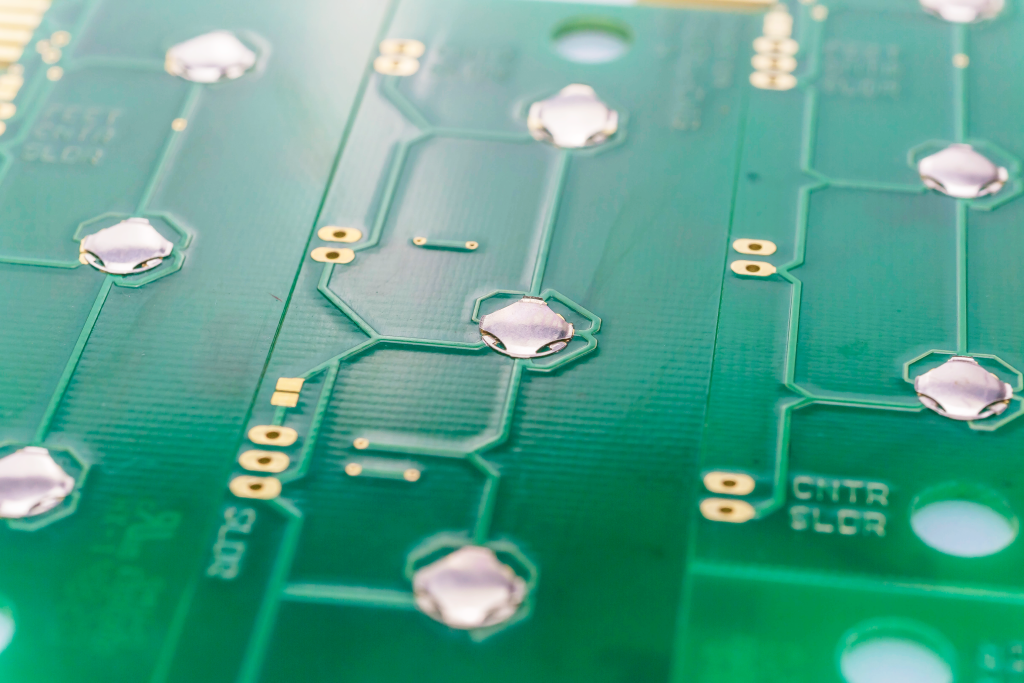

Pad Design

- Size & Shape: Match your dome’s footprint. Circular or ring-shaped pads often work best. Undersized pads reduce contact reliability; oversized pads can cause inconsistent actuation.

- Finish Selection: ENIG (Electroless Nickel Immersion Gold) is the industry standard for dome contact surfaces. It offers excellent conductivity, corrosion resistance, and is compatible with most dome types. Know your specs—ENIG thickness should follow IPC-4552 standards.

- No Solder Mask Between the Pad Contacts: Ensure that dome contacts areas are free of solder mask to maintain electrical contact integrity.

Trace Routing

- Keep traces away from dome contact areas.

- Avoid sharp turns near dome pads—these can cause uneven actuation.

- Consider adding redundant vias or traces for mission-critical switches.

Gold Plating Thickness

- Snaptron recommends a minimum gold thickness of 0.03 to 0.05 microns for ENIG surfaces, in accordance with IPC-4552 standards.

- For longer lifespan or harsher environments, consider hard gold (electroplated) and follow IPC-4556 for guidance.

Plating specifications are found at MIL-DTL-45204D, Type II, Grade C for hard gold plating.

3. Mechanical & Environmental Considerations

Let’s not forget: metal domes live in the real world. Your PCB design must account for stress and environmental conditions.

Mounting Methods

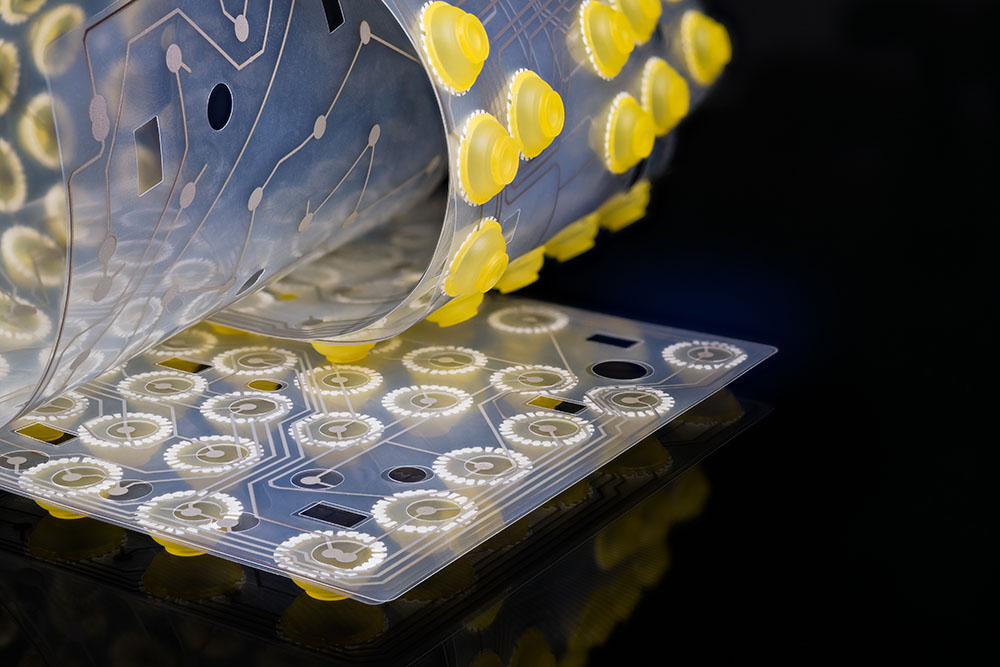

- Adhesive Dome Arrays: Great for membrane switch builds. Easy to assemble, consistent placement.

- Assembly-Constrained Domes + Overlay: More flexible, but requires tight tolerance control.

- Snaptron Peel-N-Place Arrays: Pre-aligned adhesive dome arrays ready to apply.

Environmental Protection

- Use polyester + acrylic adhesive seals or overlays to protect against dust, moisture, and abrasion.

- For outdoor or medical devices, consider a full membrane stack-up with sealing layers.

User Experience Tuning

- Adjust dome force and travel to match product expectations. For example, a medical diagnostic tool may require a low-force, quiet dome for frequent use, whereas an industrial control panel may benefit from higher actuation force and audible feedback for user confirmation in noisy environments.

Conclusion: Don’t Wing the Click

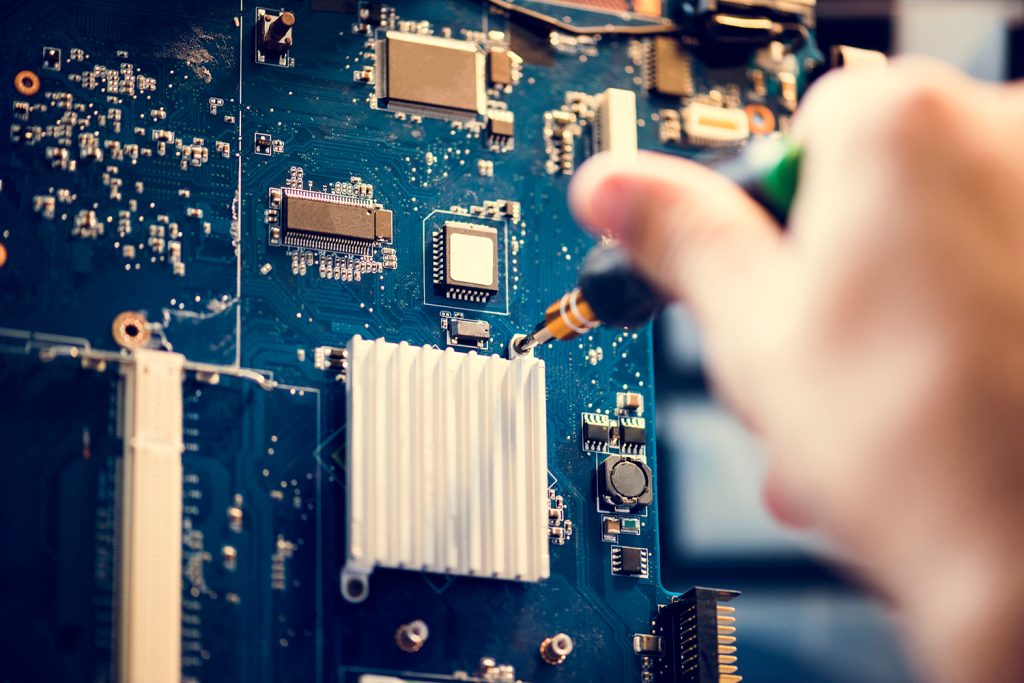

Integrating tactile metal domes into your PCB design isn’t just a mechanical afterthought—it’s central to the way your product feels and functions. Engineers who understand how to optimize pad layout, surface finish, and environmental protection build better interfaces, faster.

Need help choosing the right dome or validating your layout? Snaptron’s engineering team has seen it all—and we’re here to help.

Start your next design with Snaptron’s Dome Selector Tool or contact us for support. Let’s make your interface click.

We’ll even help you design your board. Our team of experts is available to consult on layout, materials, and switch integration to ensure your tactile interface works flawlessly from concept to production.