Overcoming design challenges to create a more responsive and reliable pedal—with Snaptron’s tactile solutions.

| Company | AirTurn |

| Location | Boulder, Colorado |

| Product | AirTurn PED 500 |

| Industry | Consumer Electronics |

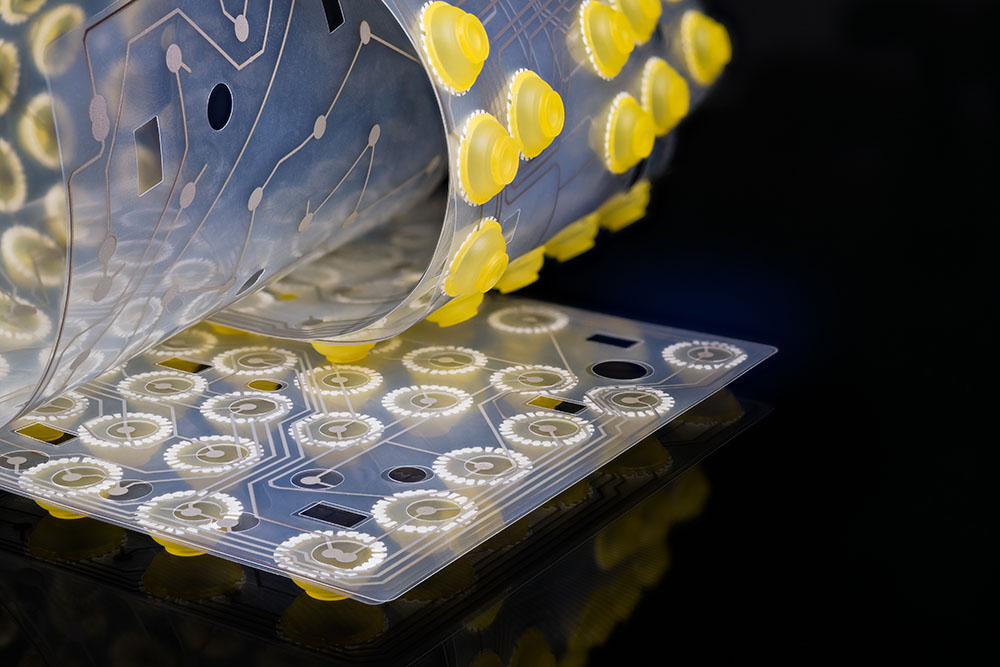

| Materials/Services Used | F08400, Custom GX251000 |

Innovation Meets Performance

For over a decade, AirTurn has been at the forefront of Bluetooth controller technology, designing products that help musicians, artists, and outdoor enthusiasts to focus on their craft without distractions. Their groundbreaking Bluetooth page turner, launched in 2007, revolutionized how musicians interact with digital content. But with innovation comes new challenges—especially when it comes to perfecting the user experience.

The Challenge: Finding the Right Feel

AirTurn’s latest pedal was designed to be sleek, lightweight, and highly responsive. But something felt off.

Users reported that the pedal’s switching mechanism, though innovative, lacked the satisfying tactile feedback they had come to expect. Negative reviews trickled in, and product returns followed. The issue wasn’t just about preference—it was about usability.

The problem lay in the interaction between the pedal’s cover and the membrane switch beneath it. If the cover pressed too far to the side, the switch failed to actuate reliably. If it did actuate, users often couldn’t feel it. AirTurn needed a solution that enhanced tactility and expanded the actuation zone without adding bulk or complexity to their design.

The Search for a Solution

President of AirTurn, Matt Dobson, and his team explored every alternative—tact switches, hall effect sensors, light sensors, and even keyboard key switches. Each option introduced new problems: too large, too noisy, or simply not the right fit.

Then they turned to Snaptron.

“We know that we can reach out to Snaptron when we have a challenging switch problem, and they will give us quick and decisive feedback,” says Dobson. “They are extremely knowledgeable not only about dome technology but also about the adjacent manufacturing processes such as molding, adhesives, and noise mitigation.”

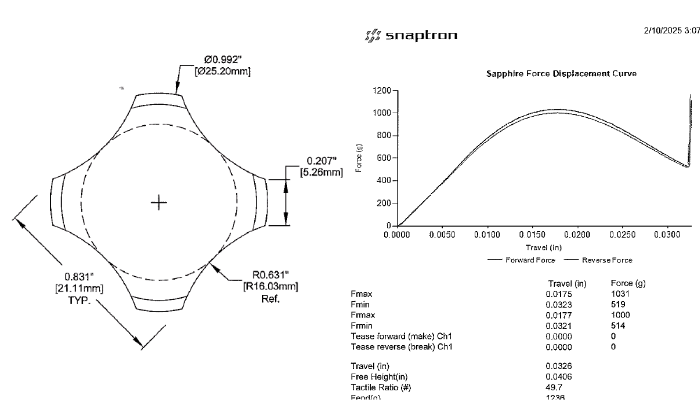

Snaptron’s tactile dome switches checked every box. They were low-profile, responsive, and durable—delivering the precise feel AirTurn needed while preserving the pedal’s sleek, streamlined design. Better yet, the partnership meant AirTurn had an experienced team of engineers ready to help refine the solution.

Engineering the Perfect Press

The collaboration kicked off with AirTurn sharing design drawings and switch samples. Snaptron’s team quickly identified the challenges and worked through multiple design iterations to fine-tune the pedal’s feel.

The breakthrough came in modifying the cover skin’s thickness in key areas. By carefully adjusting the material properties, Snaptron helped AirTurn expand the actuation zone—ensuring that users could reliably press the switch and feel the response every time.

Beyond solving the technical challenge, Snaptron also provided detailed manufacturing guidelines, making it easier for AirTurn’s production team to scale from prototyping to mass production.

Results: A Pedal That Plays in Perfect Harmony

With Snaptron’s support, AirTurn successfully launched the redesigned PEDPro, turning user complaints into rave reviews. The benefits were immediate:

- Enhanced user satisfaction – The improved tactile feedback gave musicians the confidence they needed that the device was working as intended.

- Cost savings – AirTurn avoided a costly full product redesign.

- Efficient production – Expert guidance from Snaptron streamlined the manufacturing process.

- Quicker time-to-market – Reduced development cycles meant AirTurn could deliver the improved product to customers sooner.

Beyond This Project: A Partnership That Strikes the Right Chord

Encouraged by the success of this collaboration, AirTurn has already integrated Snaptron’s domes into new product designs.

“Snaptron’s combination of dome switches and engineering support significantly contributed to the success of our redesign project,” Dobson reflects. “Their extensive experience with similar projects allowed them to provide feedback on decision points quickly. This enabled the project to proceed efficiently, and they supported us through to completion.”

Looking Ahead

AirTurn’s experience with Snaptron is a testament to how the right partnership can turn a product challenge into an opportunity. As AirTurn continues to push the boundaries of innovation, Snaptron remains a trusted partner in delivering the precision and reliability their customers expect.

When asked if Dobson would recommend Snaptron to others facing similar design challenges, he adds, “Domes are uniquely small, reliable, and cost-effective. That, combined with their support, makes partnering with Snaptron an easy decision.”