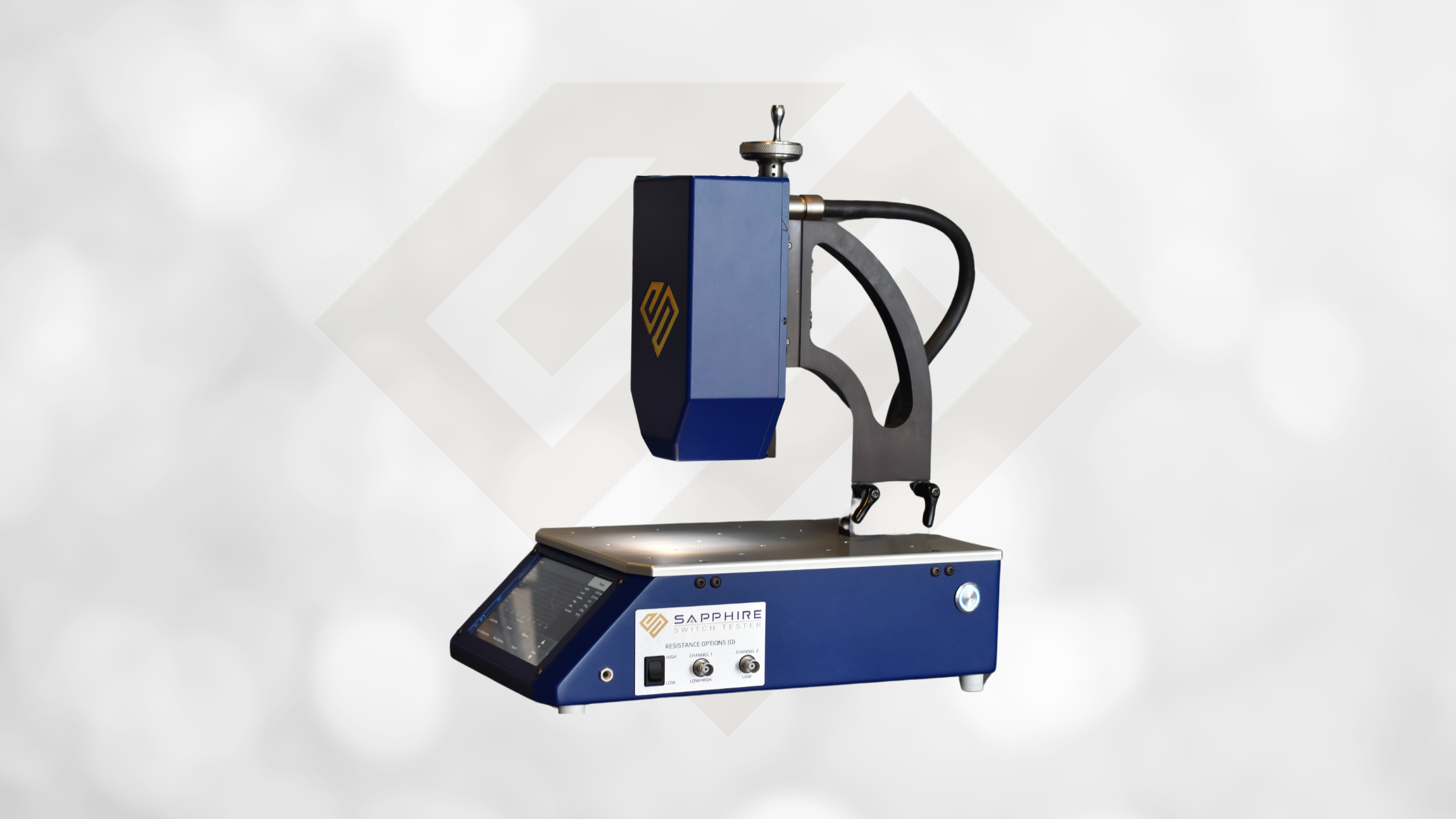

In the dynamic world of electronic device manufacturing, the importance of precision and reliability cannot be overstated. To achieve these high standards, each component, especially switches, undergoes rigorous testing to ensure optimal performance. This is where the all-new Snaptron Sapphire Force Displacement Tester comes into play. As a revolutionary tool, it is meticulously designed to meet the diverse needs of professionals in quality control and testing environments across various industries.

What is the Snaptron Sapphire Force Displacement Tester?

The Snaptron Sapphire Force Displacement Switch Tester evaluates switch performance and durability, as well as ASTM characteristics by measuring activation force and switch displacement. Notably, its key capabilities include:

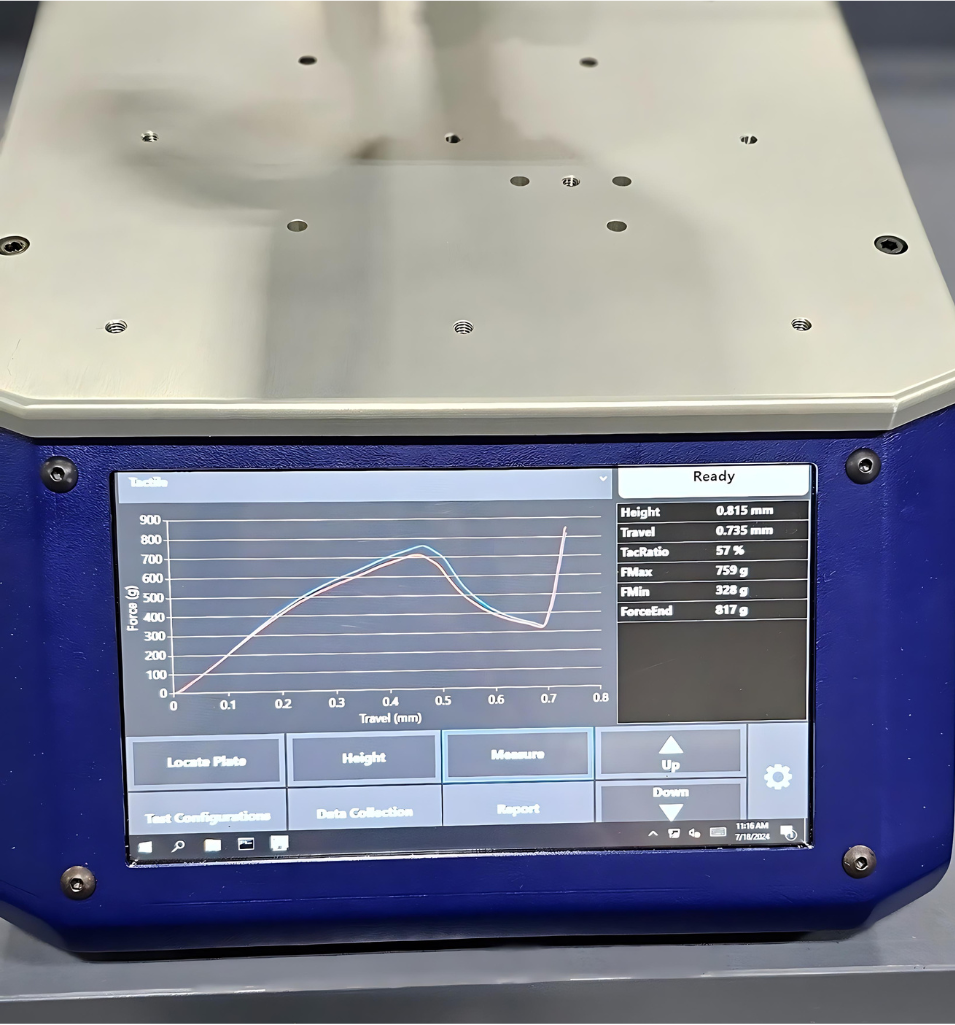

- Force-Displacement Testing: Precisely measures the force required to actuate switches and their displacement, crucial for ensuring consistent performance and durability.

- Mechanical Characteristics Evaluation: Analyzes free height, tactile ratio, and actuation force, essential for fine-tuning switch designs to meet exact specifications.

- Electrical Characteristics Assessment: Tests two-channel circuits, monitors circuit closure, and provides resistance read-outs, ensuring switches meet stringent electrical standards.

Enhanced Features for Superior Performance

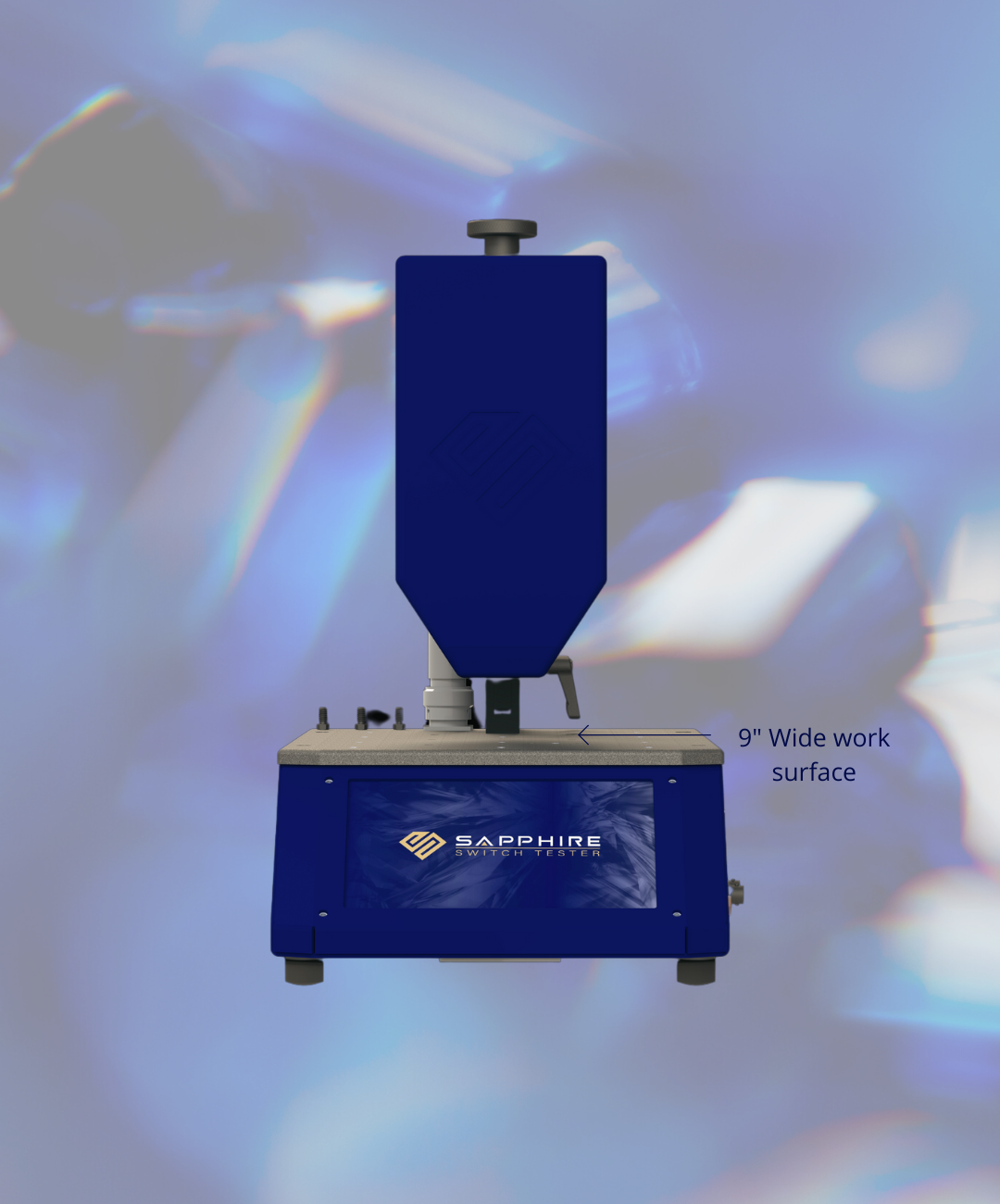

The Sapphire is more than a testing device; it’s a testament to innovation and customer-centric design. Moreover, Snaptron has meticulously crafted this new-generation model to streamline testing workflows and significantly enhance the user experience. Accordingly, here are the key features:

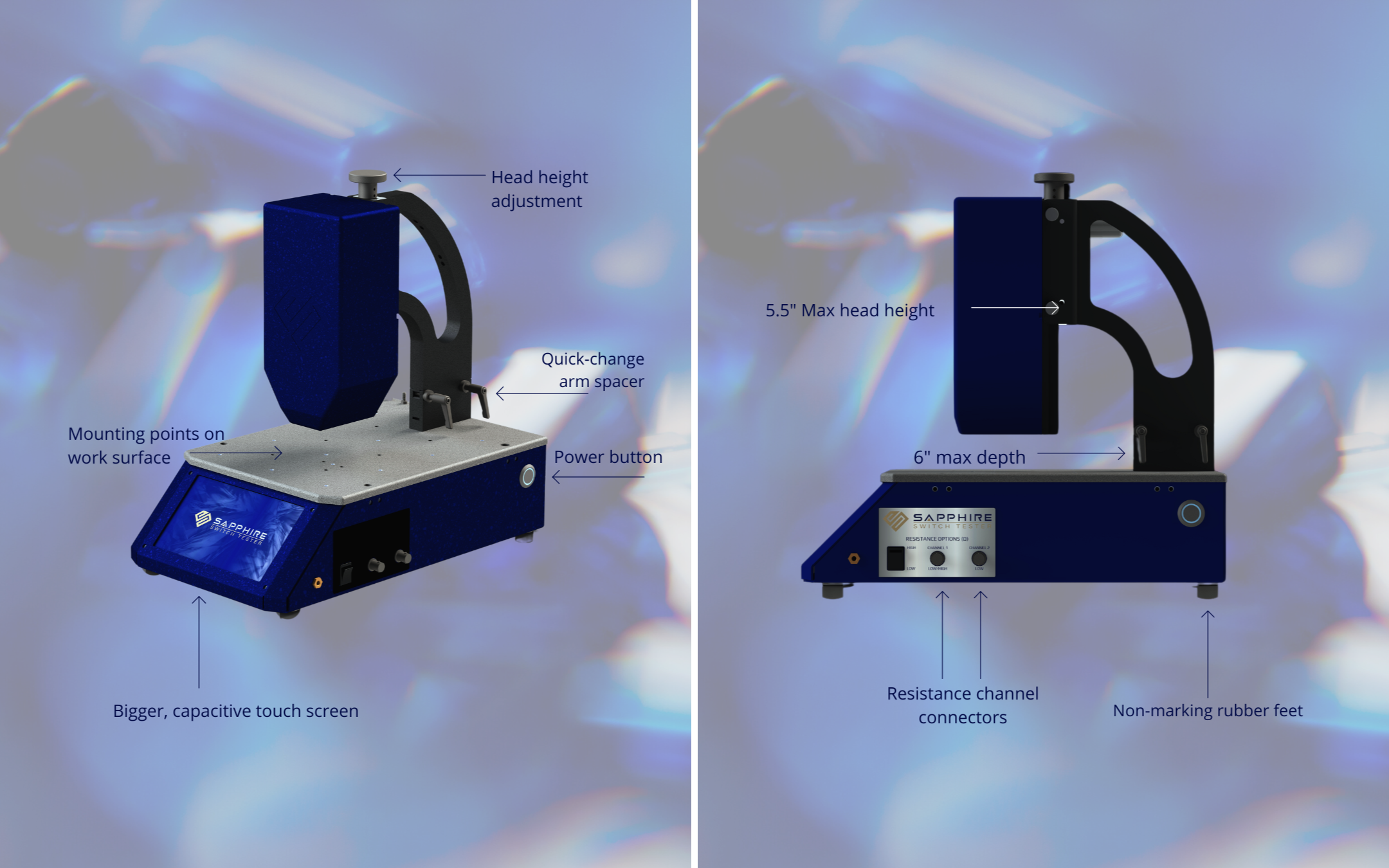

- Adjustable Head for Larger Products: The adjustable head accommodates larger products, making it versatile for testing various switch sizes and configurations.

- Bigger Capacitive Touch Screen: This feature enhances usability, offering intuitive navigation through testing procedures with greater clarity and responsiveness.

- Software Enhancements: Significant updates ensure smoother operation and seamless integration into manufacturing environments.

- User-Centric Design: Includes an HDMI port for external monitor connectivity, an externally accessible power button, and non-marking support legs.

- Non-Marking, Conductive Support Legs: The support legs are non-marking and conductive, and they ground if used on an anti-static mat or metal table.

- Simplified Vertical Adjustment Mechanism: Allows easy setup with minimal effort, ensuring precise alignment and reducing setup time.

- Integrated HDMI Output: Enhances visibility and usability during testing procedures.

- Expanded Base for Enhanced Stability: Provides consistent and reliable results even for larger applications.

- Reinforced Load Cell: Ensures the accuracy of force measurements with a durable and precise load cell.

- Fully Assembled and Ready to Use: The tester comes fully assembled and ready to test right out of the box, allowing for immediate integration into your testing workflow.

Applications Across Industries

Precision Testing for Tactile Switches in Mechanical Keyboards

Use case: A company developing a new line of mechanical keyboards needs switches that provide consistent tactile feedback and durability.

Implementation: The company used the Sapphire Force Displacement Tester to conduct precise force-displacement testing on their switches. By analyzing detailed force-displacement curves, engineers fine-tuned the switch designs to ensure uniform tactile feedback and durability across all keyboard units. Consequently, this process allowed the company to guarantee that every keyboard switch met high standards for performance and reliability, resulting in a superior product for their customers.

Quality Assurance in Automotive Switches

Use case: An automotive manufacturer requires robust switches that perform reliably in demanding environments.

Implementation: The quality control team measured activation force and switch durability using the Sapphire Force Displacement Tester. Thanks to the tester’s advanced capabilities, they ensured that the switches met stringent standards for reliability in automotive applications. As a result, this thorough testing allowed the manufacturer to confirm that their switches would perform consistently and withstand the harsh conditions typical in automotive environments, thereby ensuring high-quality and dependable products.

Electrical Characteristics Testing in Consumer Electronics

Use Case: A consumer electronics company needs to verify that the switches in their new line of smart devices meet stringent electrical standards for reliability and safety.

Implementation: The company used the Sapphire Force Displacement Tester to assess comprehensive electrical characteristics. By testing two-channel circuits, monitoring circuit closure, and providing resistance read-outs, the company ensured that each switch met the necessary electrical standards. Consequently, this rigorous testing confirmed that the switches were reliable and safe for consumer electronics. As a result, the company was able to produce high-quality and safe smart devices for the market.

Aerospace Applications for Switch Reliability

Use case: An aerospace company needs switches that can withstand extreme temperatures and conditions while maintaining precise performance.

Implementation: The company used the Sapphire Force Displacement Tester to evaluate switches for durability and performance under extreme conditions. This rigorous testing ensured the switches were reliable and safe for critical aerospace applications. By confirming the switches’ ability to endure harsh environments and deliver precise performance, the company could meet the stringent requirements of the aerospace industry and provide high-quality, dependable switches for their aerospace products.

Medical Device Reliability Testing

Use case: A medical device manufacturer needs to ensure switches in their equipment meet stringent reliability standards for patient safety and device functionality.

Implementation: The manufacturer used the Sapphire Force Displacement Tester to test switch performance and durability thoroughly. This process ensured that the switches complied with regulatory requirements and operated reliably in medical environments. By confirming the switches’ reliability and adherence to safety standards, the manufacturer could guarantee that their medical devices would function correctly and safely, providing high-quality patient care.

Conclusion

Lastly, the Sapphire Force Displacement Tester is a comprehensive solution for ensuring the reliability and performance of switches in applications. By incorporating this advanced tool into your testing workflow, you can achieve new levels of efficiency and precision. Ultimately, this will enable you to deliver superior products to your customers.

To learn more about ordering the all-new Sapphire Force Displacement Tester and leveraging its advanced capabilities to enhance product reliability across diverse industries, please visit https://www.snaptron.com/products/equipment/sapphire-switch-tester or contact Snaptron for more information.